|

|

|

| |

|

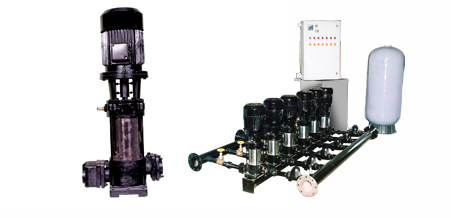

PRODUCTS >> JMLV

Pumped Liquids

Thin, clean, non-aggressive and non-explosive liquids without solid particles or fibers.

Pump

The JMLV is a non self- priming centrifugal pump with a vertical design. This non self priming pump has a mechanical shaft seal and extended pump/motor shaft is designed to occupy min. floor space, vertically mounted on base is easy and inexpensive. Std. Model of this muddy water pump is available with impellers and diffusers are made of stainless steel, sealed silicon carbide v/s silicon carbide type mechanical seal. Optional models available with all wetted parts in AISI 304, AISI 316 and PU Coating for corrosion resistance.

Motor

The JMLV series of non self priming centrifugal pumps are closed coupled with standard flange mounted fan cooled squirrel cage motor.

Normal speed : 2900 rpm.

Enclosure Class : IP 54.

Insulation Class : H.

Standard Voltages : 1 x 220-240V, 3 x 220-24/380 -415V.

Our experience as a leading sewage pump manufacturer has helped us use single-phase motors that have a built-in thermal overload protection.

Three-phase motors must be connected to a motor starter according to local regulations.

Application

Jagdish Pump Engineering Co. expertise is not just limited to being a sewage pump manufacturer in India, and we make sure that we offer various pumps that can be used across various applications. The JMLV can be used wherever high head i.e. high pressure boosting is required for clean clear fluid like booster pressure system, water circulation / transfer and water treatment plant

Pressure Boosting System :

Our non self priming pump offers a standard pressure boosting system that features a simple, conventional pressure controlled on / off control system. As a premier sewage pump manufacturer having expertise in across the board range of pumps and offer installation- friendly, compact, mounted on common frame, including all necessary accessories and internal piping. Only the required number of pumps is in operation at any given time, which gives a cascade control to help save energy. Multi pumps operation with dry running protection gives un-interrelated supply. The pressure boosting system can be also enhanced with VFD to control the requirement of sites by speed variation and adopting PID adjustment Algorithm.

|

|

|

|

|

|